Electricity is an indispensable energy source in modern human life. The power industry provides basic power for industry and other sectors of the national economy and is a leading sector in the development of the national economy. However, a variety of dangerous gases are produced in the process of electricity production. These gases are very harmful. They can cause poisoning accidents at the least and combustion and explosion at the worst, causing serious losses to the country’s economic construction and people’s lives. In order to avoid and reduce losses, it is necessary to detect the flammable and toxic gases produced in the power industry.

Due to the excellent heat transfer and heat dissipation properties of hydrogen, hydrogen cooled generator sets utilize the characteristic of hydrogen gas. The generator uses hydrogen gas as a cooling medium, and hydrogen leakage detection is required at the generator and hydrogen production station.

Combustible gas is the main fuel energy used in many places now. Combustible gas is used as fuel in boiler rooms and heating rooms of power plants. In addition, there are flammable gases in generator sets, gas pressure regulating stations, and gas tank areas. These places must be tested for leaks of flammable gases to eliminate these potential sources of danger. In addition, power plants have their own fuel storage areas, where flammable gases are also produced and leaks of flammable gases must also be tested.

There are a large number of water supply pipes in power plants, and the water supply system is prone to corrosion over a long period of time. Therefore, when adding water to the boiler, ammonia water needs to be added to adjust the pH of the water, and deoxidizers need to be added for chemical deoxidation to prevent the water supply system from being corroded. In the desulfurization and denitrification stages of power plants, ammonia is also used as a reducing agent. Therefore, there are ammonia production sites and ammonia storage areas in power plants. Since ammonia is extremely dangerous, leakage can cause poisoning and explosions, so it must be tested.

There are a lot of untreated sulfur dioxide and nitrogen oxides in the products of desulfurization and denitrification projects of coal-fired units in the power industry. In order to prevent air pollution, it is necessary to detect their content. When the content exceeds the standard, the process and ingredients should be adjusted to reduce the production of sulfur dioxide and nitrogen oxides.

Sulfur hexafluoride has good insulation properties, stable physical and chemical properties and excellent arc extinguishing performance, and is widely used in high-voltage equipment, such as high-voltage switches, high-voltage transformers, closed combination capacitors, high-voltage transmission lines, etc. It is most widely used in high-voltage transformers in power plants, but sulfur hexafluoride is one of the six greenhouse gases currently discovered. At least half of the sulfur hexafluoride gas produced annually in the world is used in the power industry, and it is still growing at an alarming rate. It needs to be strictly tested to prevent leakage and air pollution.

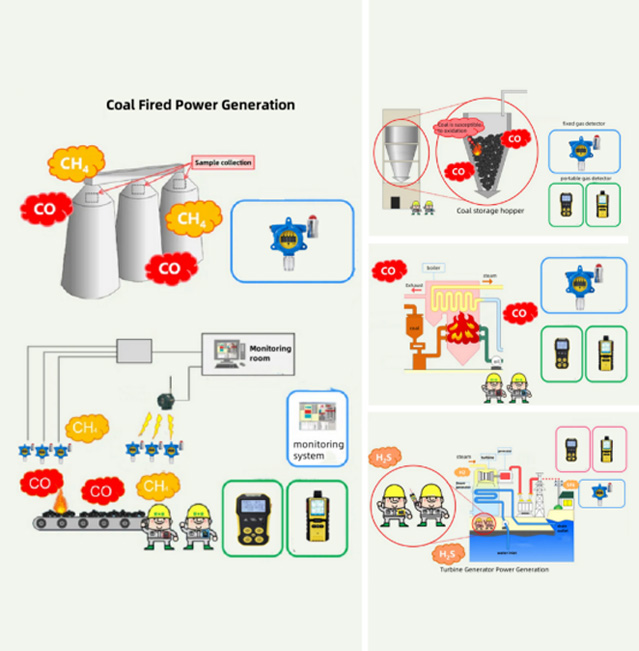

Coal-fired Power Generation

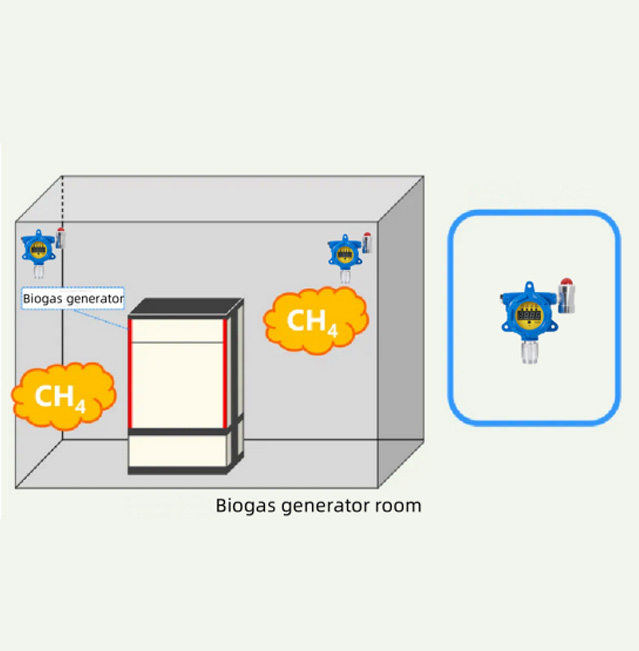

Biogas power generation

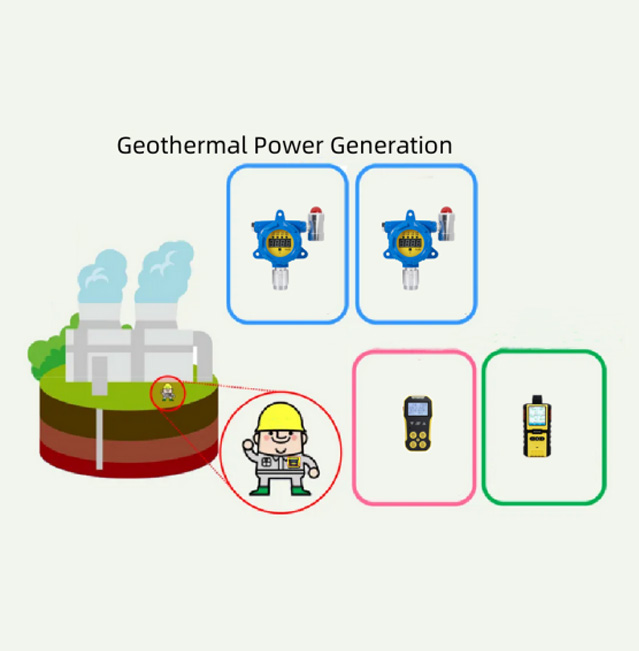

Geothermal power generation

Coal is sent to the coal bunker for temporary storage, and then the coal in the bunker is transported to the coal storage hopper through a belt conveyor according to the operation of the power plant. Coal is burned in the boiler to produce high-temperature and high-pressure steam, which drives the turbine impeller to rotate, thereby driving the generator to generate electricity, using hydrogen and other refrigerants. The substation is equipped with a "transformer" that controls the voltage of the power transmitted by the generator and a "circuit breaker" that cuts off the power in the event of an accident. These devices use sulfur hexafluoride (SF6) as an insulating gas.

Coal has the risk of spontaneous combustion during storage, so it is important to detect the CO produced by low-temperature oxidation of coal in the early stages. The closed environment and coal oxidation lead to the risk of hypoxia, so the oxygen concentration in the environment must be measured to prevent hypoxia. The concentration of hydrogen used as a refrigerant in coal-fired power generation also needs to be tested. Sulfur hexafluoride (SF6) as an insulating medium in substations also needs to be noted.

Biogas power generation uses organic waste such as livestock manure, food waste, and sewage to ferment and extract combustible biogas (methane), which is then used to generate electricity through gas engines or gas turbines.

Biogas is a mixed gas, its main components are methane and carbon dioxide.CH4 leakage in the biogas generator room may cause explosion, so portable and fixed detectors should be used to detect the concentration of CH4 to ensure the safety of workers and prevent explosion.

Geothermal power generation is to extract geothermal fluid from geothermal reservoirs, vaporize the geothermal fluid through a separator (steam-water separator), or vaporize a secondary medium through geothermal fluid, and use the generated steam to rotate a turbine to generate electricity. Geothermal fluid contains carbon dioxide (CO2), hydrogen sulfide (H2S), ammonia (NH3), methane (CH4), etc., as well as sulfur dioxide (SO2).

H2S and SO2 leaking from the condenser manholes, power rooms, culverts and other equipment in geothermal power plants pose a risk of poisoning, and H2S and SO2 need to be monitored to prevent poisoning.